Service hotline:

+86 0769-83513659 +86 188-9842-7928

Product CenterSpecializing in the R & D, production and sales of screen printing and other equipment

classification

All the products you need are here

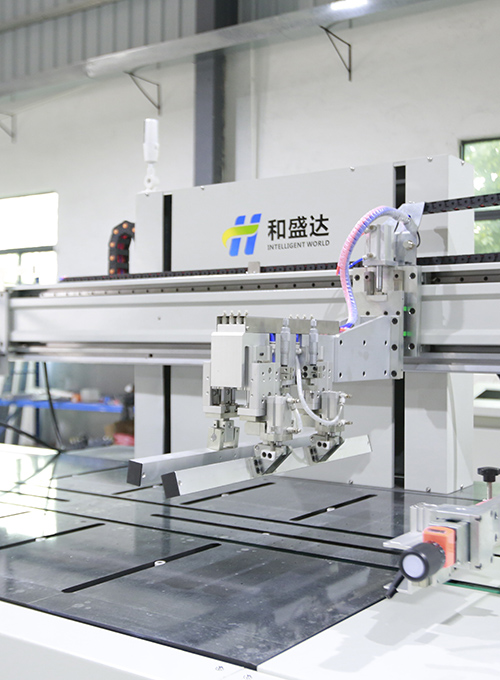

Automotive glass (triangle window) printing machine

Automated production solution for high-quality printing requirements for automotive and window glass Use upper positioning structure for irregular glass positioning Shuttle servo transmission...Product applicationMainly for automobile, solar energy, home appliances, engineering and other industries of glass printing equipment

Up to 72 hours of simulated production simulation testA number of testing standards to ensure that the factory equipment meets the standard requirements

R & D teamProvide customizationQuality assuranceService hotline:+86 0769-83513659

Choose heshengda's four advantagesMultiple testing standards ensure that the delivered equipment meets the standard requirements

fully reinforced

be even quality

R & D team

after-sale service

Strong production strengthStrong production strength

Specializing in screen printing and other equipment research and development, production and sales of enterprises. I mainly have profound experience in glass printing equipment, auxiliary equipment and manipulator of automobile, solar energy, household appliances, engineering and other industries, as well as sharp and intelligent adaptability.

Stable product qualityProduct quality is stable

Products through strict production technology, a number of testing standards, to ensure that the performance meet, excellent material selection, after standard inspection, quality assurance, product variety, complete specifications, supporting ability.

Strong R&D teamStrength R & D team

We can according to your different needs, tailored for you to create exclusive personalized product solutions, simple operation, stepless speed adjustment; Professional personalized design, easy operation and maintenance.

After-sales serviceIntimate after-sales service

7*12 hours customer service hotline, all aspects to provide pre-sale, sale and after-sales service, adhering to the tens of millions of users to provide peace of mind, rest assured service purpose.

Walk into · HeshengdaFocus on glass screen printing equipment for many years

Heshengda (Dongguan) Automation Equipment Co., LTD., is a professional engaged in screen printing equipment research and development, production and sales of enterprises. I mainly have profound experience in glass printing equipment, auxiliary equipment and manipulator of automobile, solar energy, household appliances, engineering and other industries, as well as sharp and intelligent adaptability. The main members of the company are the core members who have been the industry's top customers for many times and successfully completed innovative projects. At the same time, we can also provide precise support in equipment upgrading and transformation. In the new line project, we can provide customers with integrated turnkey project services from layout, scheme, process, training, service, optimization of cost performance and so on.

Follow us to learn more about glass screen printing equipment

Walk into Heshengda

Company profile Equipment Contact usProduct center

High Efficiency Auto Glass Printing Line Fully self-made glass screen printing machine Fully automatic engineering glass printing line Fully automatic printing press More...Product application

Automotive glass screen printingHome appliance glass screen printingBathroom glass screen printingNews Center

News Center Technical Support Common problem+86 0769-83513659

Person in charge Tel: +86 139 2371 0886/Mr. Cheng Director of Sales: +86 188 9842 7928/Dina E-mail: 66014197@qq.com address: No.1, Hefu South Street, Helu Village,Mobile QR code

WeChat public account

WeChat applet

Heshengda (Dongguan) Automation Equipment Co., Ltd. Copyright © 2022 [Admin] Technical support:Dongguan Website construction